Dynamic Cycle™

A Sustainable initiative

in support of plastic circularity

Taghleef Industries’ (Ti) focus is on innovating sustainable products that meet real needs and support a more balanced lifestyle. As we do this, we aspire to go above and beyond—to set ourselves apart while we take initiative to pioneer new ways to contribute within and beyond our industry, set new standards, demonstrate a difference, and plan for generations ahead.

Dynamic Cycle™ is Ti’s set of initiatives aimed at addressing sustainability issues within and for our industry, our partners, our communities, and our stakeholders. It translates into strategic choices, advanced know-how, a focused investment strategy, and the most compliant portfolio. It is Ti’s trusted consulting voice that interacts with all our partners to contribute to the quality of life for generations to come.

Commitment

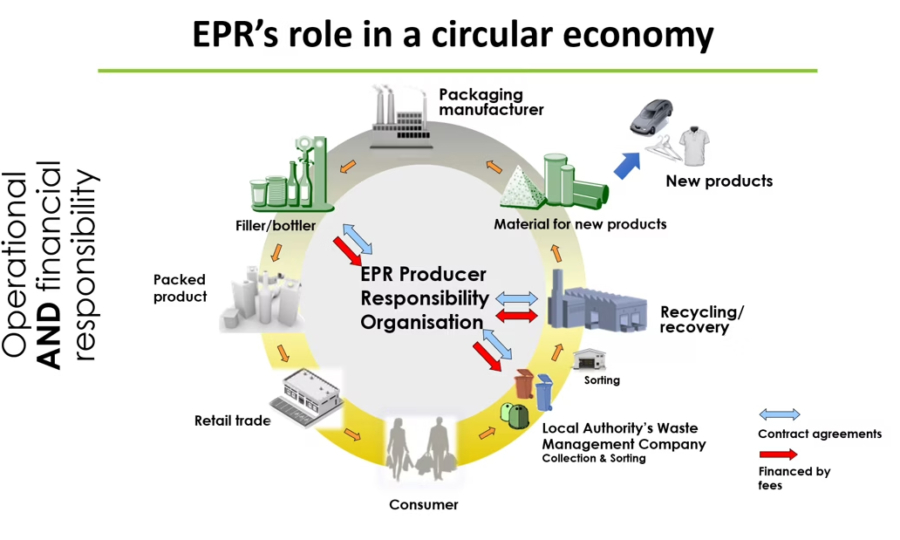

Dynamic Cycle represents Ti’s commitment to truly closing the loop, not just through our internal circular economy projects but also by collaborating with various organizations, supporting different causes, thus contributing to a positive change in the environment and society.

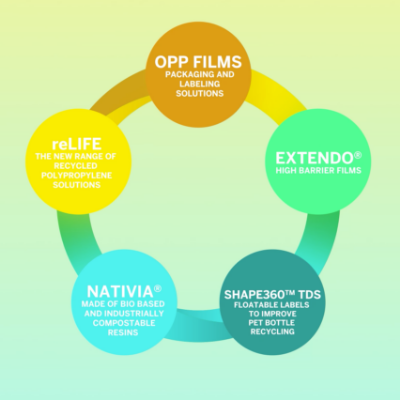

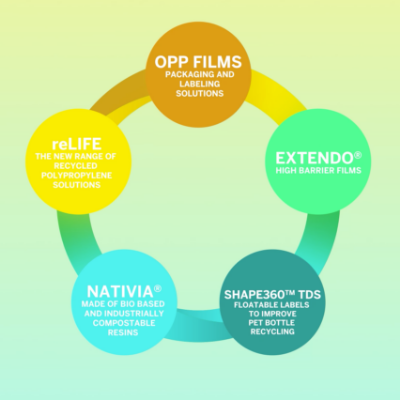

Solutions

Dynamic Cycle Solutions offer our customers access to superior range of outstanding film solutions in the market, combining sustainability, innovation and performance needs – from films that help protect products, avoid food waste and improve hygiene, to films with low carbon footprint and recycled content. Ti is part of the solution.

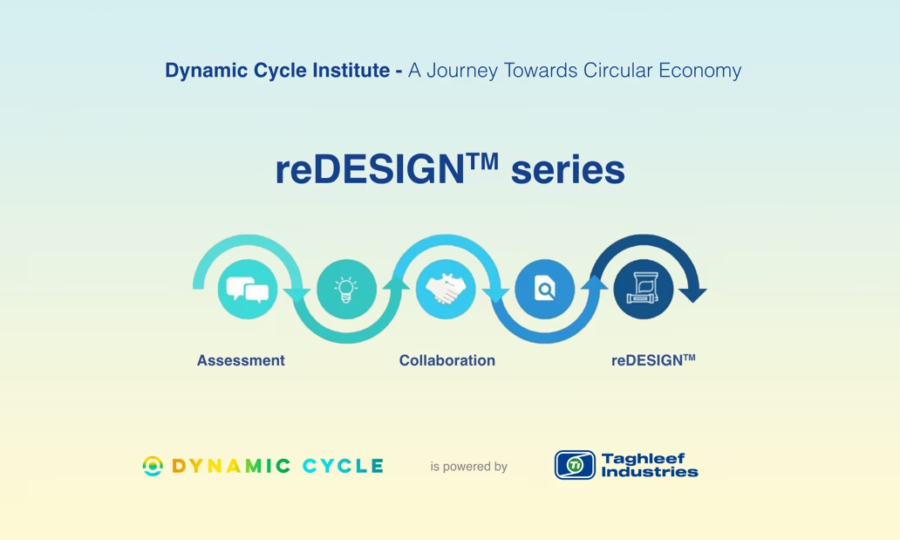

Services

Dynamic Cycle services are value-added offerings that meet our customers’ spoken and unspoken needs. Through Ti’s reDESIGN™ service, our industrial experts collaborate with customers to arrive at the best possible solutions—for them and for the environment.

Taghleef also provides a set of verified measurements, such as CFP and Life Cycle Analysis (LCA) studies that demonstrate the proven benefits of the films we use.

Contact us to reDESIGN your packaging together.

Corporate Goals

Dynamic Cycle’s approach to Sustainability is holistic: it embraces different aspects of the business, setting Sustainability at Ti‘s core.

Dynamic CycleWebinars

Not sure where to start?

Try our Products Finder and find

any of our films in an instant

Customize a more sustainable, innovative solution that best meets your specific requirements